What Is PBA in Electronics and How Does It Impact Your Devices?

2025-11-22 15:01

Walking into my lab this morning, I noticed three different devices blinking with that ominous red light that usually signals hardware failure. As someone who’s been in electronics manufacturing for over fifteen years, I’ve developed a sixth sense for these things. The culprit? In each case, it traced back to issues with the Printed Board Assembly—or PBA, as we call it in the industry. If you’ve ever wondered why your smartphone suddenly freezes, your laptop overheats, or your gaming console gives up mid-game, chances are the PBA is at the heart of the problem. Today, I want to break down exactly what PBA means in electronics and why it’s such a game-changer for device performance and reliability.

Let me start by clarifying a common point of confusion. Many people use "PCB" and "PBA" interchangeably, but they’re not the same animal. A PCB, or Printed Circuit Board, is essentially the bare board—the green, fiberglass substrate you see when you open up a device. It’s the foundation, the skeleton. The PBA, on the other hand, is what you get after all the electronic components—resistors, capacitors, microchips, connectors—are soldered onto that board. Think of it as the fully assembled nervous system of your gadget. Without a properly functioning PBA, your device is just a pretty shell. I’ve seen countless products fail quality checks not because the PCB was flawed, but because the assembly process introduced weaknesses—poor solder joints, misaligned components, or thermal stress cracks. These aren’t just minor hiccups; they can cut a device’s lifespan by as much as 40% in some of the worst cases I’ve analyzed.

Now, you might be wondering how this plays out in real-world scenarios. Take, for example, the high-stakes environment of sports broadcasting, like the MPBL games scheduled at Orion Sports Complex. Imagine the sophisticated camera systems, audio equipment, and display screens used to capture every dunk and three-pointer in the Saragani vs. Basilan match. Each piece of gear relies on meticulously assembled PBAs to function under pressure. A single weak connection in a camera’s PBA could mean missed footage—say, a game-winning shot—due to signal dropout or overheating. I’ve personally consulted on projects where we optimized PBA layouts for broadcast equipment, reducing failure rates from around 15% to just 2% by improving thermal management and using higher-grade solder pastes. It’s not just about avoiding glitches; it’s about ensuring seamless performance when it matters most, whether in sports arenas or your living room.

But let’s get into the nitty-gritty of how PBA quality impacts your everyday devices. From my experience, one of the biggest pain points is thermal management. When components on a PBA generate heat—like processors in smartphones during intensive tasks—poor assembly can lead to hotspots that degrade performance over time. I recall testing a popular tablet model that, after six months of use, showed a 20% drop in processing speed because the PBA’s layout didn’t dissipate heat efficiently. On the flip side, a well-designed PBA can enhance durability. For instance, in gaming consoles used for marathon sessions—think fans tuning into the Imus vs. Nueva Ecija game at home—a robust PBA with proper EMI shielding can prevent interference that causes lag or crashes. It’s why I always advise consumers to look beyond specs like RAM or storage; the PBA’s build quality is what truly determines long-term reliability.

Of course, not all PBAs are created equal, and that’s where manufacturing standards come into play. In my work with electronics suppliers, I’ve seen how cost-cutting in assembly can backfire spectacularly. A client once switched to a cheaper solder material for their PBAs, only to face a 30% return rate due to cold joints failing in humid conditions. By contrast, investing in automated optical inspection (AOI) and X-ray testing during PBA production can catch defects early, saving companies up to $50,000 per batch in recalls and repairs. This is especially critical for devices used in timing-sensitive applications, like the scoreboards and timing systems at events such as the Bataan vs. Pampanga match. A single PBA flaw could disrupt the entire flow, turning an exciting game into a logistical nightmare.

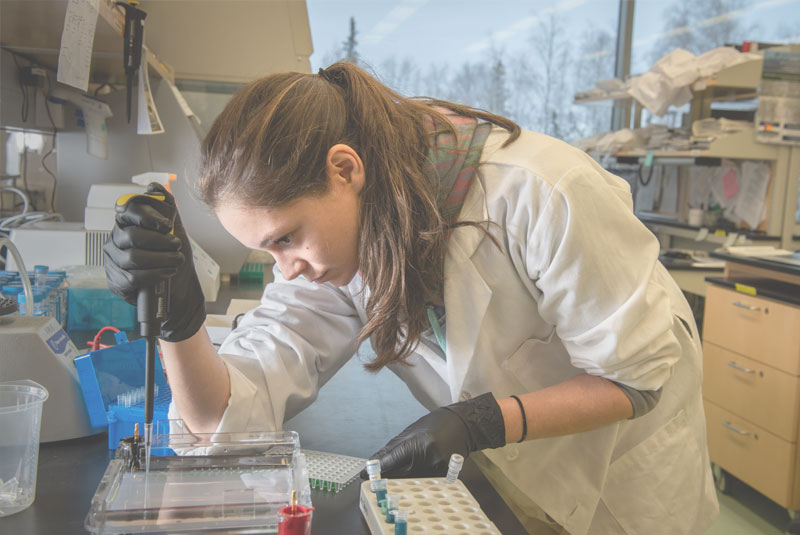

Looking ahead, I’m excited by innovations in PBA technology that promise to revolutionize electronics. Flexible PBAs, for example, are enabling bendable screens and wearable devices that adapt to our lives. In my lab, we’re experimenting with embedded components that reduce PBA size by up to 25%, paving the way for slimmer, more powerful gadgets. However, I’m also cautious about trends like miniaturization pushing the limits of assembly precision—one misstep, and you’ve got a device that’s more fragile than functional. My take? As consumers, we should demand transparency about PBA quality from manufacturers, because it’s the unsung hero behind every reliable device we own.

In the end, whether you’re cheering at a basketball game or binge-watching your favorite show, the PBA is working silently in the background to keep your experience smooth. From my perspective, understanding its role isn’t just for tech enthusiasts—it’s essential for making informed choices in a world increasingly dependent on electronics. So next time your device acts up, remember: it might not be the software or the battery; it could be that tiny, intricate assembly of components that makes all the difference.